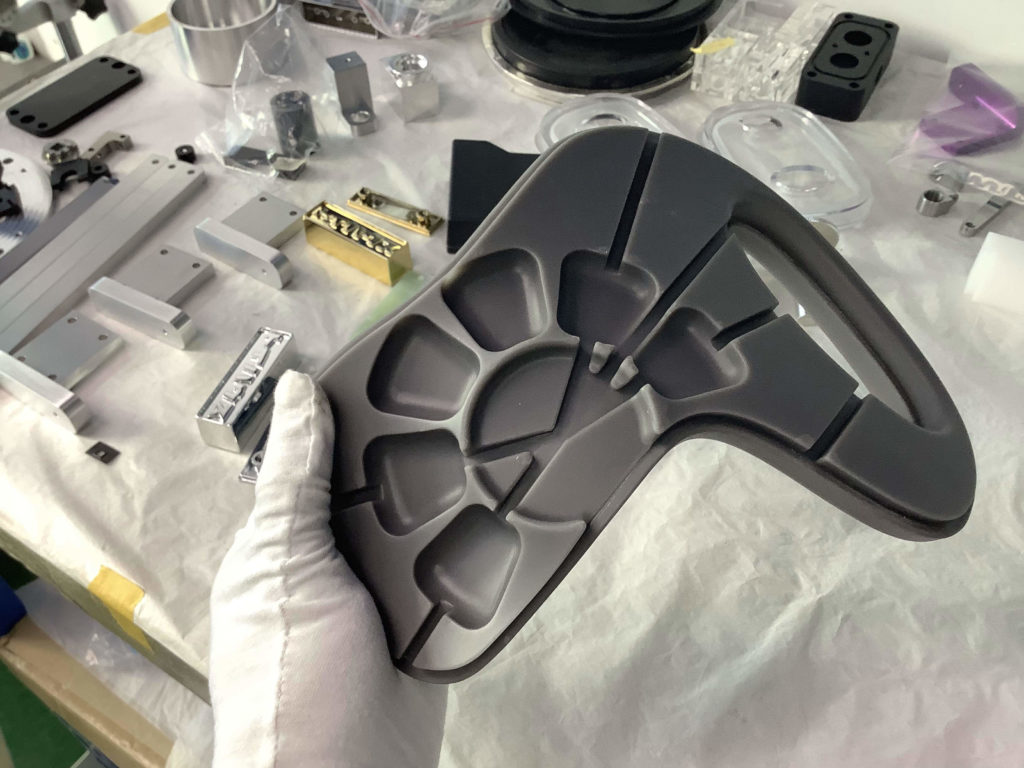

Vacuum casting is a great way to make rigid or flexible parts, and is ideal for prototypes, engineering testing, concept proofing and display demos. These parts can be made from hundreds of casting polymers.

Leadpoint is fully capable of handling your vacuum casting and silicone molding needs. With years of expertise in the field, we can fabricate your parts to the highest standard and with fast turnarounds.

Leadpoint can provide up to 20 parts in 15 days or less, depending on part specification and volume.

Silicone molds are less expensive than the tooling used for injection molding, resulting in low prices.

Depending on the type of equipment used, vacuum casting can to create very large parts.

The vacuum process removes air bubbles and allows the material to capture fine details.

Coloring pigments can be added to the resin for a variety of color options.

Silicone molds can be used around 20 times before they need replacing.