Professional Prototyping & Low Volume Manufacturing Services from China

We aim to be your Reliable Prototyping & Low-Volume Manufacturer : include CNC Prototyping, 3D printing SLA and SLS, Vacuum Casting, Sheet Metal Fabrication, Plastic Injection Molding and Die Casting and various Post Surface Finishing solutions.

Leadpoint committed to offer turnkey solution for rapid prototyping & rapid tooling services, we specialized in CNC Machining, CNC Milling, Turning, Sheet metal fabrication, prototype to Low volume production, Metal surface finished as Plating, Anodized, chrome, Nitriding, heat treatment, black oxide coating and more. As a provider for non-standard parts machining for automotive, medical, aerospace, energy, electronic and other industry. Hope our sincere services could have your trust and support!

Plastic: ABS, PC, ABS+PC, PP, PS, POM, PMMA (Acrylic), PAGF30, PCGF30, Teflon, DHPE, HDPE, PPS, PEEK etc.

We chiefly present plastic prototype with materials such as ABS, PC, ABS+PC, PMMA(acrylic), PP, POM, bakelite, PTFE(Teflon), MC(nylon), PEEK, etc. Other plastic material sorts are arrangeable.

Commonly applied surface finishing technique on plastic prototype are matte, polishing( especially for transparent plastics), spray painting, screen printing, hair-line dealing, etc. A product can be finished by composite techniques and looks unique and beautiful.

Metal: Aluminum, Steel, Stainless Steel, Magnesium, Titanium, Zinc, Brass, Bronze, Copper etc.

The material we commonly use to make metal prototypes are such as aluminum, zinc, copper, iron, stainless steel, etc. Other metal material sorts are arrangeable.

Metal prototypes can be dealt with finishing technique including most of which able to be used on plastic one. Besides, sandblasting, electroding, aluminum coil polishing, electrocoating, electroplating also are common techniques we use to satisfy customers’ various appearance demand.

· CNC Multi – CNC Milling / CNC turning Lathe / Wire EDM

· MOLDING – Injection mould / Injection Molding

· SHEET METAL – Bending / Stamping / Laser / Water / Punching

· FINISHING – Electro-plating / Powder coating / Anodizing / Silk-screen printing

· 3D PRINTING – FDM / SLA / SLS

BENEFITS – Why Us?

Competitiveness :

Thanks to our production means in Asia, we offers you very competitive prices.

Efficiency :

A dynamic and qualified experienced team will meet all your expectations.

Expertise :

Our various technologies and finishings provide high-end prototypes.

Lead time :

Production within 3-15 days and delivery by plane (Fedex, DLH, TNT).

Confidentiality :

Each project remains confidential and we provide Non Disclosure Agreements.

Quantity– From 1 to 1000+ custom parts, metal and plastic material

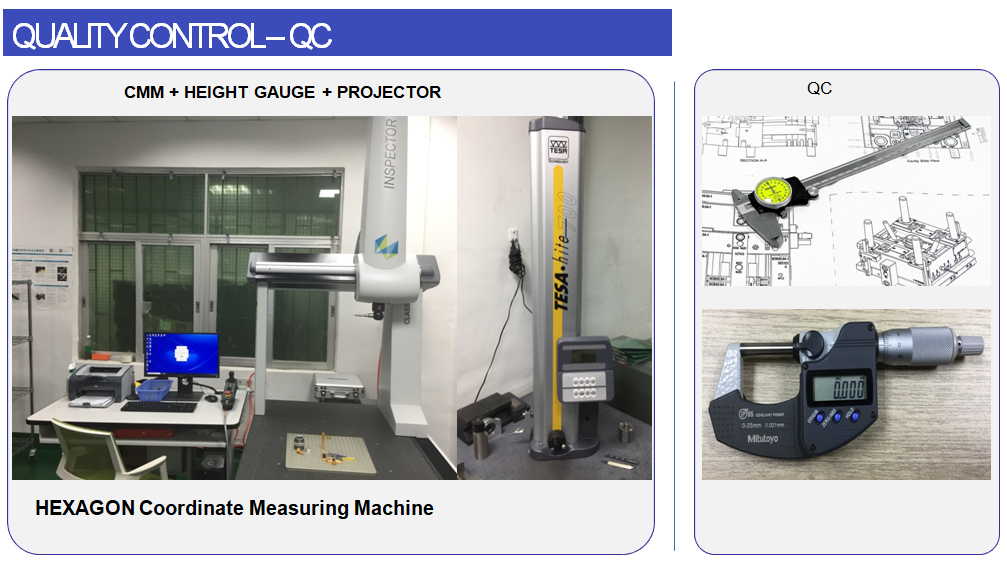

Quality Control – We equipped with variety of inspection instrument and very serious and responsible team in their job to ensure our defect-free products.

Integrity and Honesty – Being integrity and honesty is our business rules.

Client first – Our aim is to make you more successful in what we do, we will work with you to earn the respect and satisfaction of your client. We seek and listen carefully to your feedback.

A People company – Our wealth is our people. We valued talent and strive to attract and training the best people.

Your reliable partner in China! – We offer you the high quality, competitive and the fastest turnaround prototyping services.