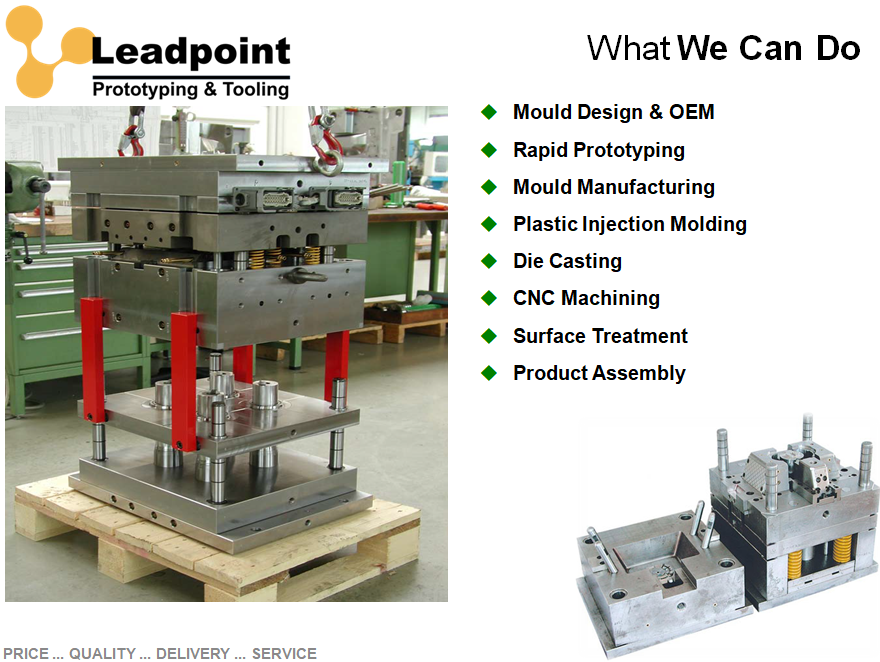

Leadpoint is a full service custom injection molder. We are equipped with a complete inhouse tool construction and maintenance facility. Some of the services we provide include the following:

Our advantages are as follows:

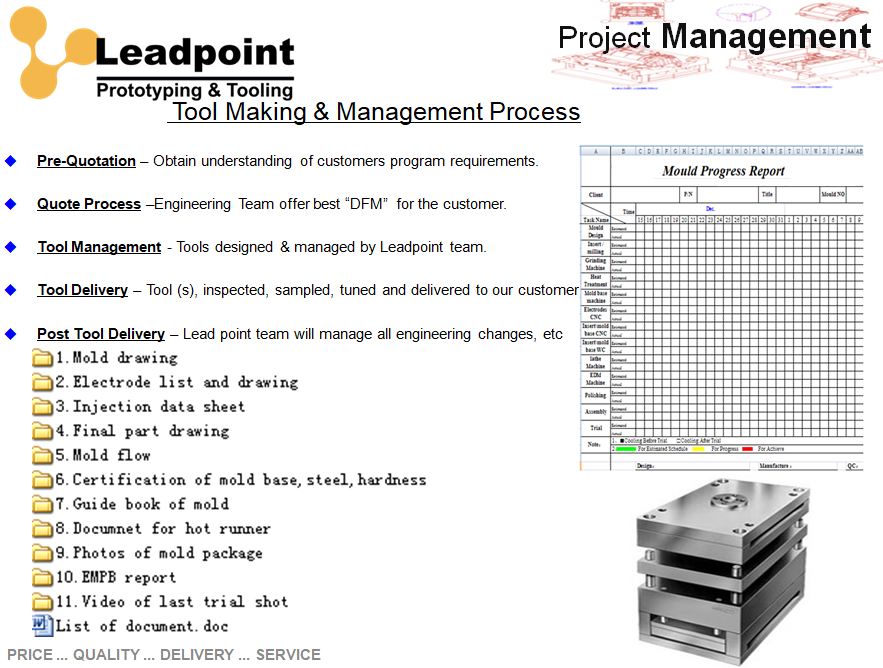

• Reliable and Responsible Service supply by good project management staff

• Good Quality and Competitive Price Base on manufacturing plant.

• Short Lead Time

• Quickly Response for Your Requirements

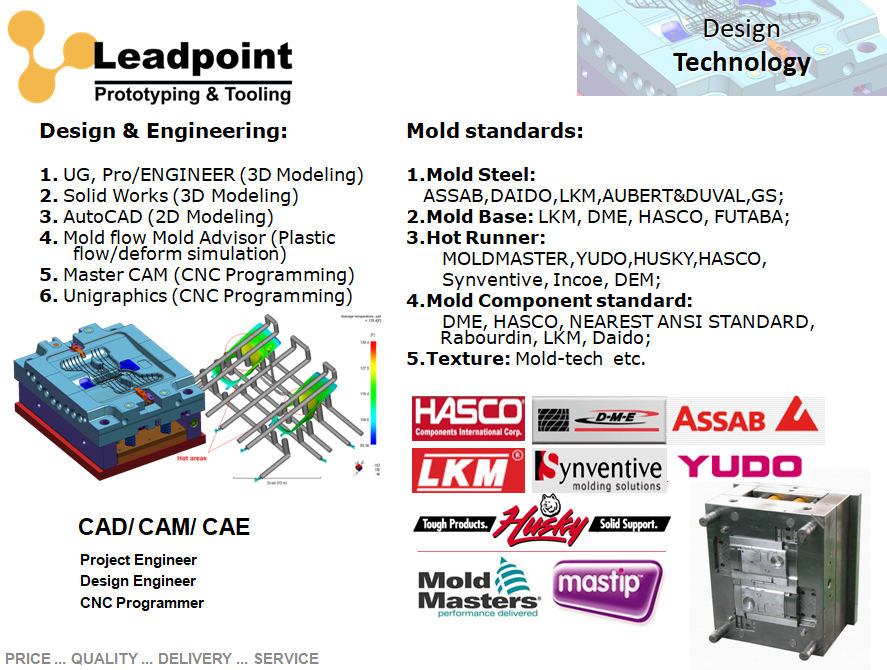

• Strong Engineering Capability

• More than 16years experiences in mold tooling

Leadpoint is a full service custom injection molder. We are equipped with a complete inhouse tool construction and maintenance facility. Some of the services we provide include the following:

Injection Molding Materials:

Finishing:

Little to no finishing is required on injection molded parts because the desired textures and finish levels are applied to the mold cavity.

Our Quality Control Procedure including:

| Document and Data Check |

| Mold design Inspection |

| Mold Core & Cavity Steel Dimension and Hardness Inspection |

| Test at each machining procedure (CNC,EDM,Polishing,etc) |

| Mold Test Report & Samples Inspection |

| Pre-mass production sample test |

| QC Hourly inspections on every part with approved samples – CPK |

| Mold Package Inspection |