Leadpoint

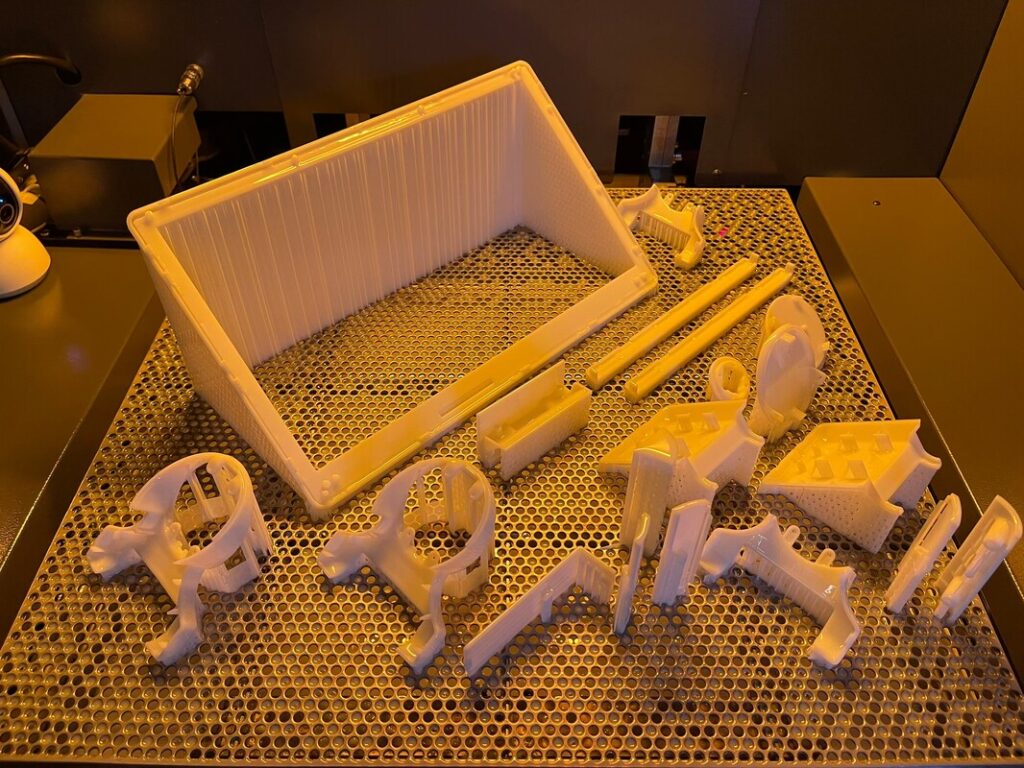

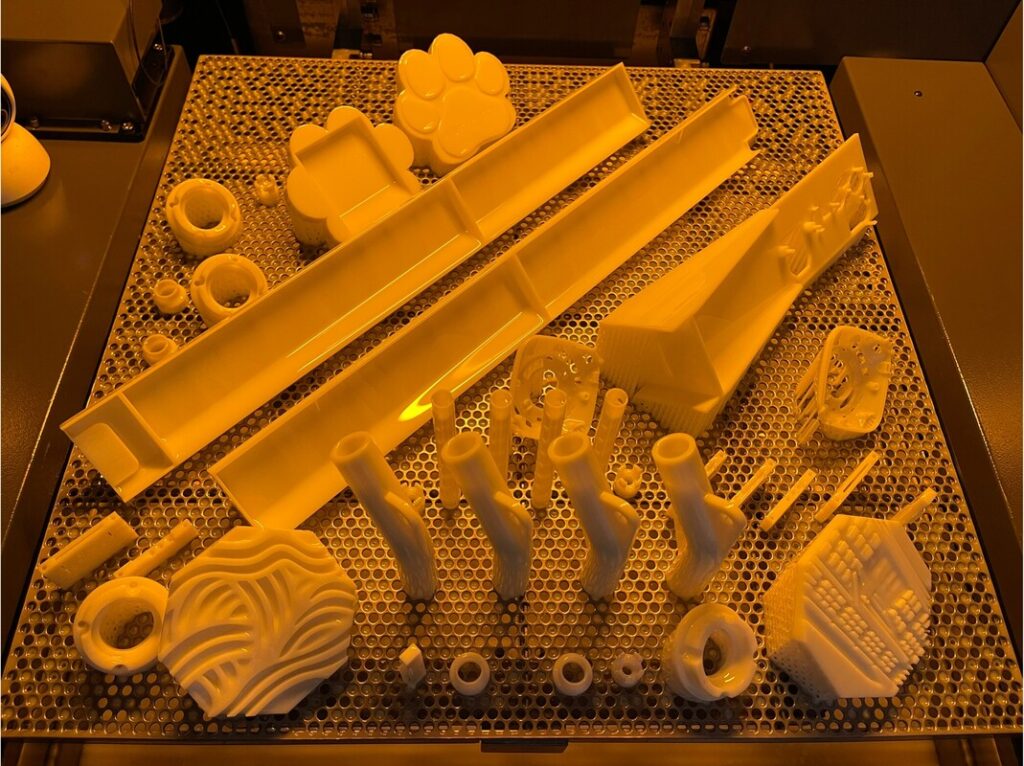

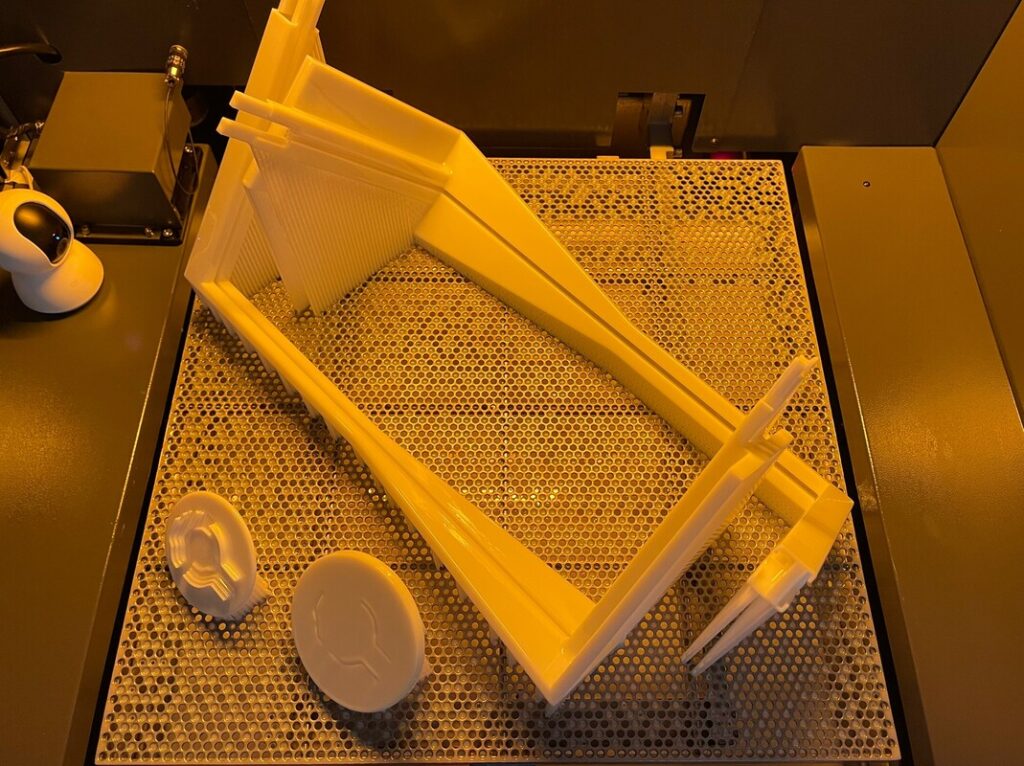

3D printing is the most common resin 3D printing process, popular for its ability to produce highly accurate, isotropic, and waterproof prototypes and end-use parts. SLA 3D printers produce parts with a range of advanced material properties, superior surface finishes, and fine features.

Leadpoint is here to take you through how SLA resin 3D printers work, why thousands of professionals use this process today, and how SLA printers can benefit your work.

What is Stereolithography (SLA) 3D Printing?

Stereolithography, also known as vat photopolymerization or resin 3D printing, is an additive manufacturing process in which a light source cures liquid resin into hardened plastic.

Of all 3D printing technologies, SLA 3D printing offers the fastest speed, highest resolution and accuracy, sharpest details, and smoothest surface finish. Another major advantage of resin 3D printing is the wide range of materials available. Material manufacturers have created innovative SLA resin formulations with a wide range of optical, mechanical, and thermal properties to match the performance of standard, engineering, and industrial thermoplastics.

Rapid Prototypes & On-Demand Manufacturingmakes it faster, easier, and more efficient for your projects