We chiefly present plastic prototype with materials such as ABS, PC, ABS+PC, PMMA(acrylic), PP, POM, bakelite, PTFE(Teflon), MC(nylon), PEEK, etc. Other plastic material sorts are arrangeable.

Individuals or enterprises make mockups of plastics sometimes because of the more economical cost compared to metal mockups.

Usually, plastic prototypes have the properties of their lightness, elasticity, and non-conductivity compared to metal prototypes.

Commonly applied surface finishing technique on plastic prototype are matte, polishing( especially for transparent plastics), spray painting, screen printing, hair-line dealing, etc. A product can be finished by composite techniques and looks unique and beautiful.

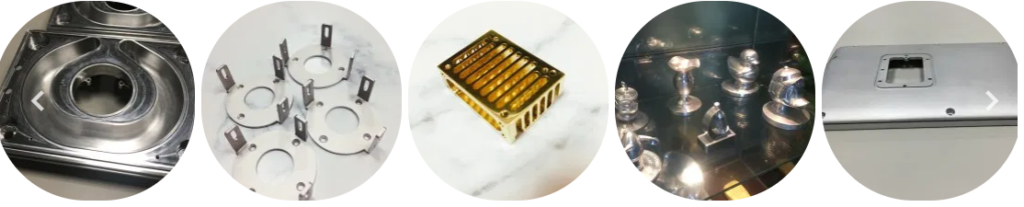

The textures we commonly use to make metal prototypes are such as aluminum, zinc, copper, iron, stainless steel, etc. Other metal material sorts are arrangeable.

People choose metal as their prototype texture usually because of its hardness, conductivity, heat conduction, tenacity, acid and alkali resistance. But there is some weakness such as heaviness, rusty, oxidization, etc.

Metal prototypes can be dealt with finishing technique including most of which able to be used on plastic one. Besides, sandblasting, electroding, aluminum coil polishing, electrocoating, electroplating also are common techniques we use to satisfy customers’ various appearance demand.

Notice that the CNC processing of metal prototypes is non-detachable because they are hardly adherable.