| With many years of continuous growth and expansion, Leadpoint build-up rich experiences on various process and raw material through continuous new equipment investment to meeting customers ever growing new requirement across different industries. |

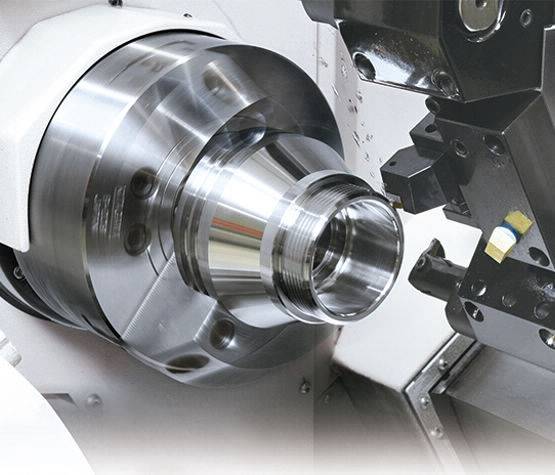

| Machining Process • Turning • Turning with C-Axis • Milling (3-Axis & 4-Axis) • Horizontal Milling |

Post Process

• Ultrasonic Cleaning

• Electrolytic Polishing

• Passivation

• Glass Bead

Welding Process

• Resistance Welding

• Arc Welding

• Laser Welding

• Laser Cladding

Assembly

• Semi-product assembly

• Final-product assembly

Typical Raw material we are using:

| Stainless Steel: 303, 304, 304L, 316, 316L, 416, 420, 430, 440C, 630(17-4) … Carbon Steel: 1018, 1045, 1144, 12L14, 1215… Aluminum: 2011-T3, 2017-T4, 5056, 5052, 6061-T6, 6061-T4, 6082-T6, 6063-T6, 7075… Brass: C3602, C3604… Special Alloy: Monel, Inconel, 0Cr18Ni8, 465, 316M94 … Plastic: POM, PEEK, PPSU … |