When a product needs to be produced in small batches, silicone molds are generally used for production. Many designers do not understand silicone molds. Below Leadpoint will introduce to you the common process problems of silicone molds for product shells.

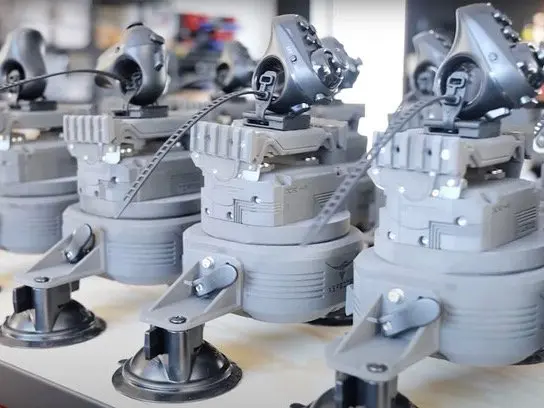

Silicone mold replication refers to using the original sample to make a silicone mold under a vacuum state, and then casting it with PU, silicone, nylon ABS and other materials under a vacuum state to clone a replica that is exactly the same as the original.

Features of silicone molds: no need to open molds, low processing costs, short production cycle, high simulation, suitable for small batch production, etc. Silicone molds are favored by high-tech industries, which can speed up the progress of research and development and avoid unnecessary waste of funds and time costs in the research and development process.

How many times can silicone molds be used?

15-25 times

Silicone mold materials:

ABS, PC, PP, PMMA, PVC, rubber, high temperature resistant materials and other silicone mold materials.