Leadpoint has three devices for inspection tasks, and we use different devices for different tolerance types. We classify tolerances into two types – geometric tolerances and dimensional tolerances. Typically, CMMs are arranged to inspect geometric tolerances because #CMMs can use probes to make contact with specific locations on the part being inspected and accurately calculate the results.

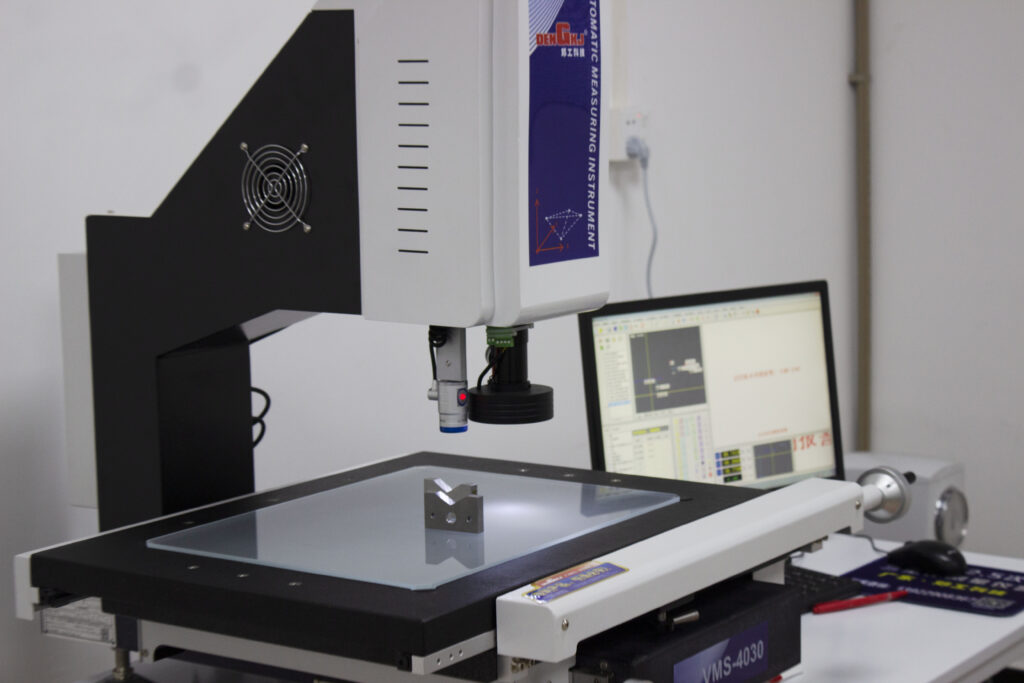

Image size inspection systems are often used when there are many identical parts to check for dimensional tolerances and angles. The device is smart enough to calculate the length and width results by itself through the headquarters CMOS.

Please choose Leadpoint and let us present your design perfectly!