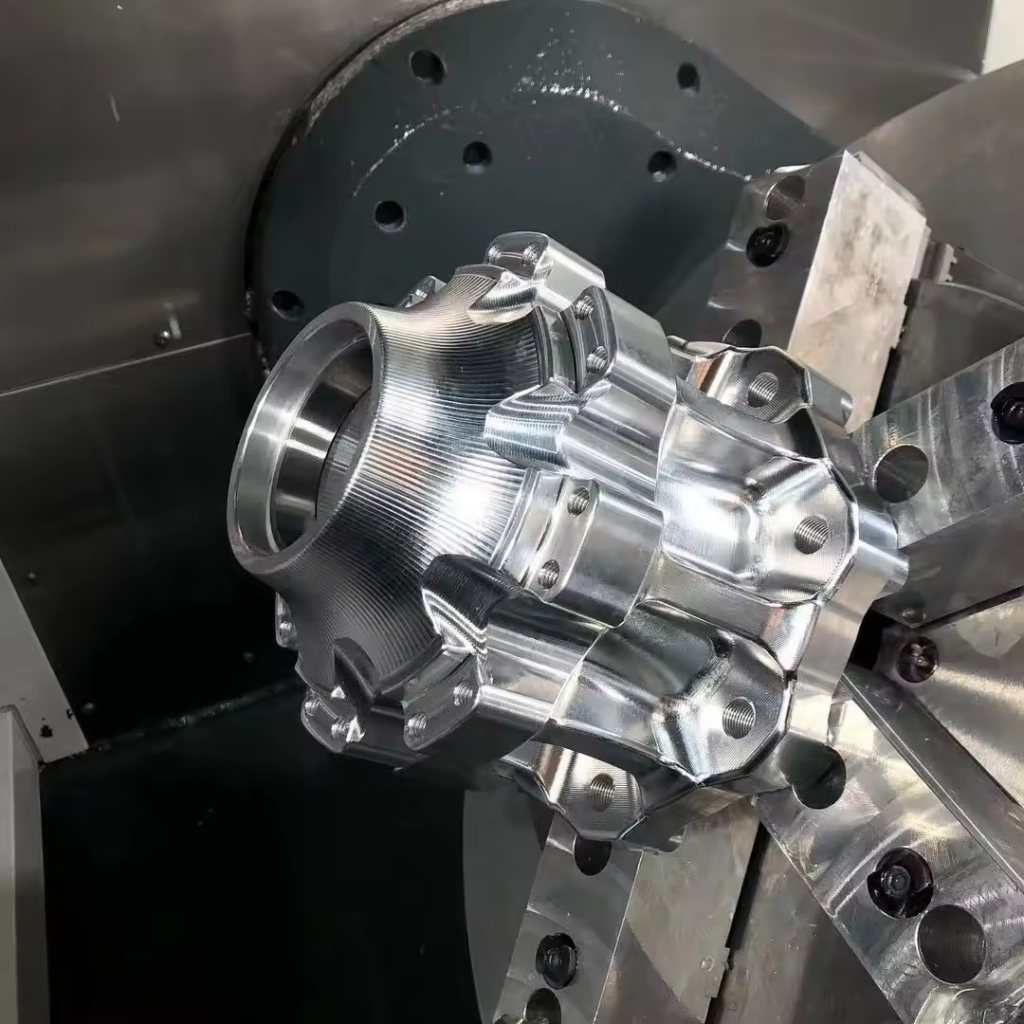

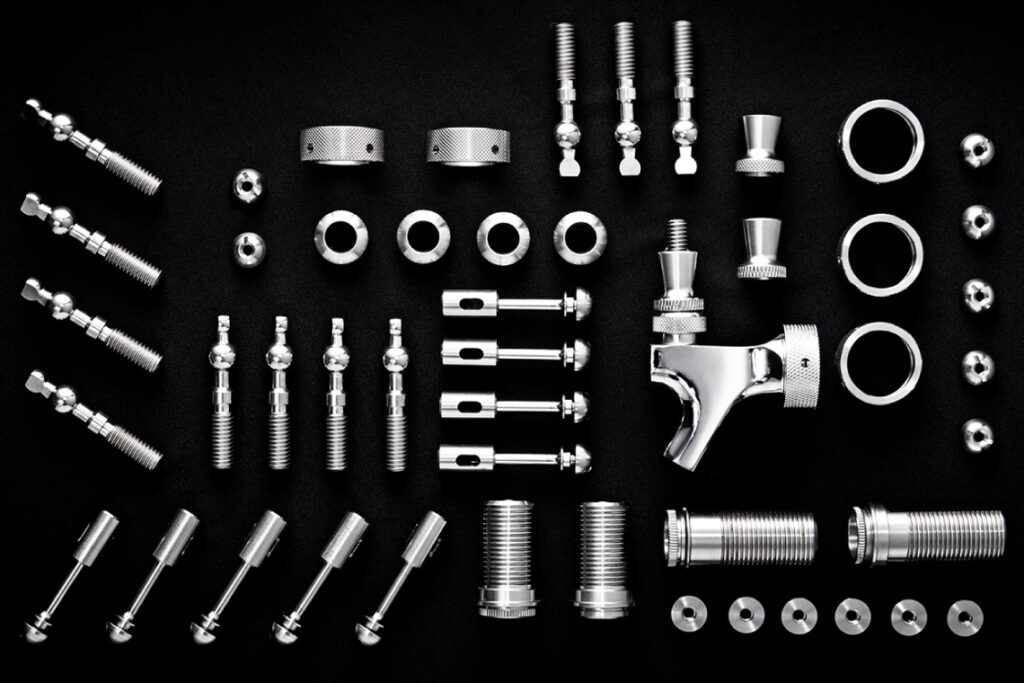

Leadpoint offers advanced 5-axis CNC milling, which greatly expands the possibilities of manufacturing parts of various shapes and sizes. We have the ability to handle all types of aluminum milling projects that require high-precision and complex-shaped machined parts, and provide extremely tight tolerance control and excellent surface finish to meet your most difficult manufacturing challenges.

Advantages of 5-axis milling of aluminum parts

With only one clamping, 5 sides of the part can be machined, saving setting time and improving machining efficiency.

Higher precision and excellent surface finish improve the overall machining quality of the part.

The workpiece does not need to flow between several processes, reducing errors and fixture costs, and reducing manual operation time.

Multi-angle milling and drilling, due to tilting the tool/worktable to maintain the best cutting position and constant chip load, improve tool life and extend the service life cycle.

Shorter and harder tools can be used, achieving higher spindle speeds and feed rates while reducing the load on the cutting tool.